Seamless Tube

Cu-Ni Alloy Tube

Copper Nickle tubes are used in major ship building and freshwater facilities, as well as in he construction of gas and oil petroleum plants. RMK has been providing these Cu-Ni Tubes to major clients in Southeast Asian countries and Middle East clients. At RMK, in order to meet our client's demand for different lengths of pipe, we are offering a uality range of Copper Nickle Tube. Manufactured at vendor's end using supreme quality materials and sophiscated machines, RMK can provide tube dimesion between 1.5 mm (min) to 259 mm (max). Additionally, RMK has the capability to produce maximum length 32 meter long pipe.

Brass Alloy Tube

Admiralty Brass is an Copper Zinc Alloy, and contains small amount of tin and arsenic as well. These admiralty brass tubes are renowned for their characteristic of superior corrosion resistance in a moderately polluted river water and clean seawater, both stagnant or slow moving water. The most common and wrought form is tube for heat exchange equipment. These tubes are extensively used in various applications including; evaporators, condensate coolers, heaters, vent condensers, water heaters, generator, air coolers, turbine oil coolers for petrochemical, ship-building, power plants, desalinations plants etc.

Copper Alloy Tube

RMK has produces different range of heat exchanger tubes as seamlessly drawn smooth tubes in various copper alloys in all relevant dimensions. High-precision surfaces and dimensions form the basis for the exceptional quality of our products. Our ability to supply tubes in fixed lengths eliminates the unnecessary waste entailed when customers must cut tubes to size. Copper alloys impress with their excellent properties: - High Heat Conductivity - Excellent corrosion resistance

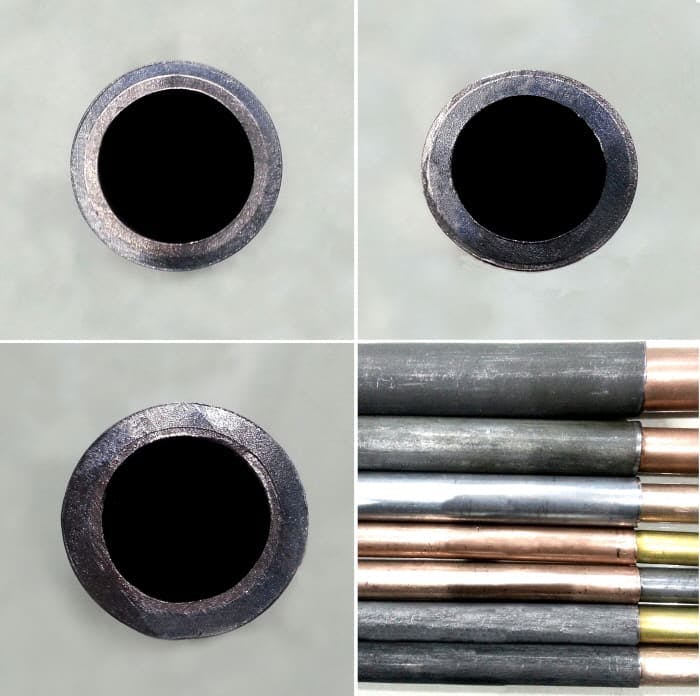

Carbon Steel Tube

Carbon steel pipes are mainly used for low and medium pressure boilers, petroleum casing tubes, ships, fluid conveyance, petroleum crakcing and structures and pumping rod. At RMK, we can produce minium OD of 1.5mm to maximum OD of 168.28mm. Our products have been producing and selling them to worldwide customers in Europe, USA, Southeast Asia and Middle East. We have previously manufactured carbon steel pipes A178, A179, A192, (Carbon Steel Tube & Alloy Tube), with SCH 30, SCH 40, SCH 80, SCH 160 and so on. RMK can produce maximum length of 32 meters long tube, which is the longest available in South Korea. Our products are used top EPCs and large corporate clients in Middle East, Vietnam and other major countries.

Stainless Steel Tube

Stainless Steel Pipes are often used in applications that require rigid materials for potable water conveyance. Manufacturers select stainless steel because certain manmade materials have unwanted or unknown exposure effects while stainless steel has many desirable qualities for maintaining clean water. Steel tubes can also be used for structural support in buildings and vehicles. The terms “tube” and “pipe” are generally interchangeable, although technically, “tube” implies heightened engineering qualities. Tubes are generally manufactured based on standardized sizes.

Clad Tube & Pipe

The environment required low price and high quality needs more efficient materials, clad tubes and pipes meet the requirement of high durability, corrosion resistance. By using clad materials, engineers make their decision more easily for sour service and reduce a period of construction. Bi-metal CRA has strong resistance to HIC & SSCC environment. RMK TUBE has 10 years experience for producing clad tubes & pipes. Cladding two different materials by cold drawing makes possible fast production and reliable quality. We have a patent of Bi-metal tubes & pipes issued by Korea Institute of Patent Information. Cladding by cold drawing covers defects of expansion method which is influencing with mechanical properties of base metal. It can save appx. 70% of the price comparing with the existing way, reduce lead time. Any materials that clients need, for example, Titanium, Tantalum, Cu-Ni Alloy, Stainless Steel, Ni Alloy, we can use as inner and outer tubes & pipes. We are manufacturing the tubes and the pipes size from Ø15.88mm to Ø168.28mm, 10.55~11.8m length.

U-bended Tube

RMK Tube is providing one stop solution from tubing to bending in one place. It minimizes time and cost. as well as decreases the entire price of the tubes. After bending, the tubes are checked by strict quality management procedure. Heat treatment chart shall be provided with other quality documents when the u-bending tubes are ordered by our clients. Generally, above 100mm radius are not required to have treatment, in case of carbon steel (CS) & stainless steel (SS).

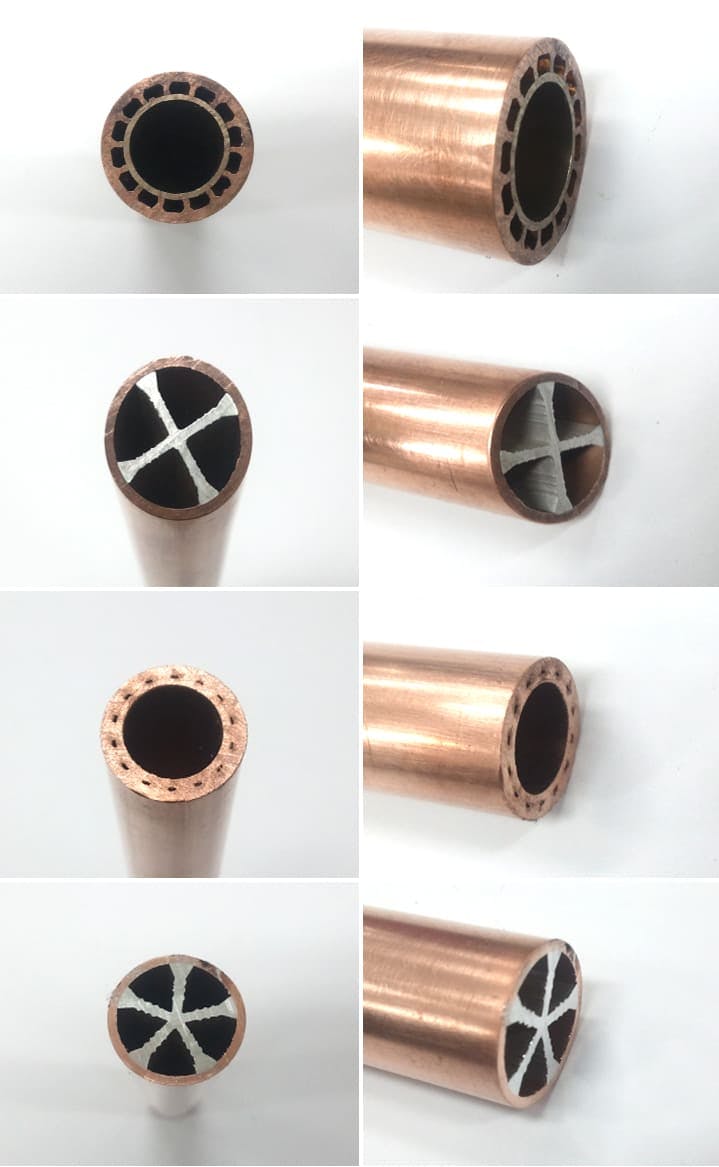

Special Tube

In marine business area such as battle ship, tubes with integrated holes in double walls can be used for serveral reasons. It prevents corrosion & leakage and at the same time, maximizes surface area to achieve high efficiency of heat transfer. Most of all, the space between two walls minimizes impact from outside. Under bad environment, it guarantees good condition. Integral finned tubes with 5 & 4 lines also provide high efficiency of heat transfer. It maximizes the surface of inside of tubes, heat can be moved to the surface of the tubes more easily. The efficiency of heat transfer is more higher than the tube with integrated holes in double walls, but it can't block any damage from outside due to it has single wall. Also user can choose different gas in each hole. Inputting 4 kinds of gas into each space ,for example, user can mix them at final stage as its use. At starting point, the gas is very stable and it makes totally different kind of gas at the final. Fittings and seals for these materials will be provided with and it will be total solution for your project.